Decarbonizing Planet Earth by Better Utilizing Carbon

Governments, corporations, regulators, and investors seem to be focused on hydrogen as the centerpiece of global decarbonization. Everyone is talking about it. Tax incentives and government grants are being implemented to advance the hydrogen economy. And why not? Hydrogen burns with no carbon emissions and can be made from water. It’s the most abundant element in the universe.

The answer to decarbonization thus far has been threefold: first, make hydrogen from renewable power; second, put CO2 underground; and third, totally abandon fossil fuels. Although there are some valid arguments for each of these objectives, there is a better way forward: decarbonization by better utilizing carbon, especially CO2 that is currently being vented to atmosphere.

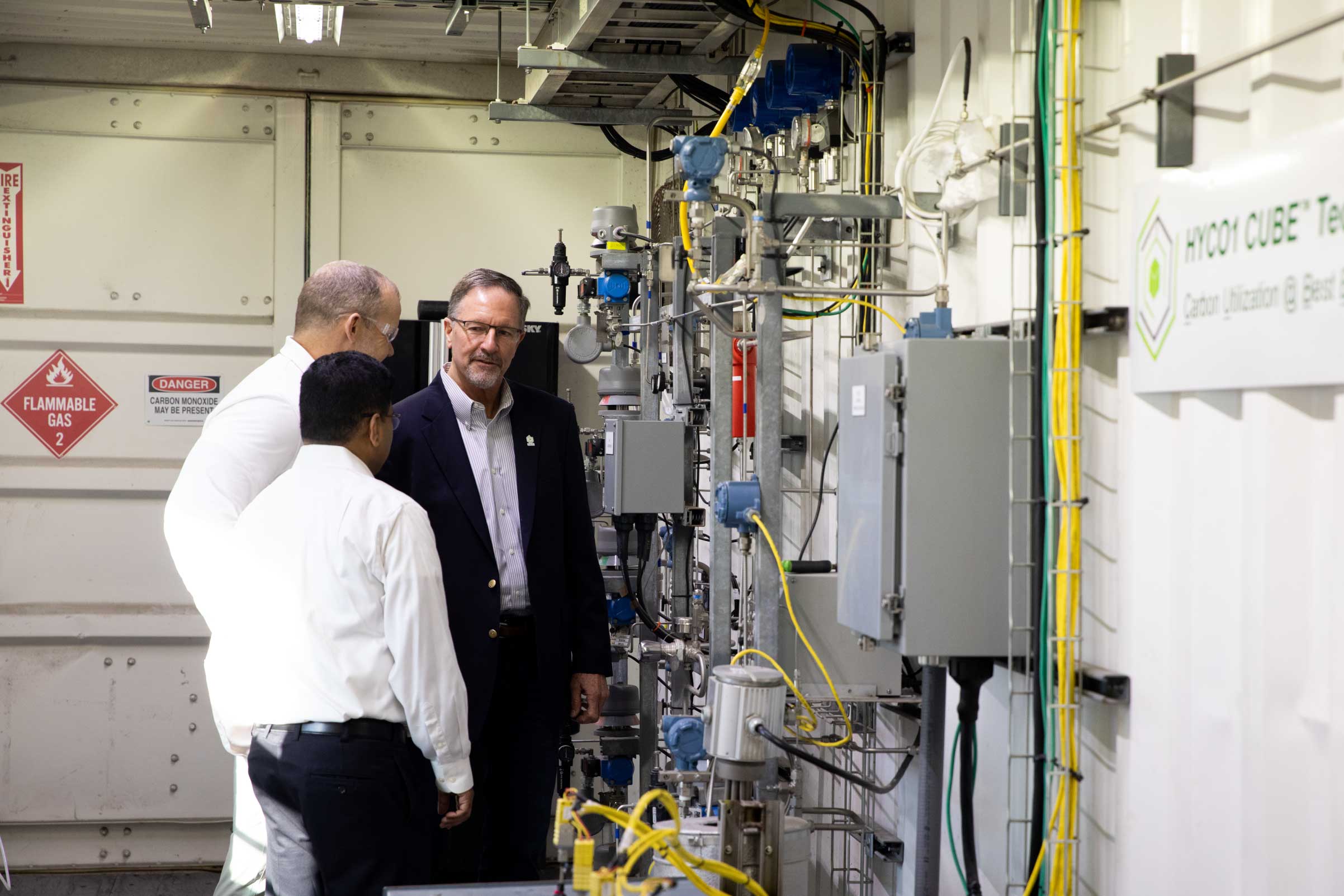

HYCO1’s breakthrough technology – called HYCO1 CUBETM Technology – allows CO2 and CH4 to be used as primary feedstocks to co-produce hydrogen alongside carbon monoxide. Huh? Is the typical reaction most people have when they hear this statement. And that reaction is quickly followed by “Oh no, you can’t use any fossil methane and decarbonize the world – just isn’t possible.” The “purists” argue that the only true way forward is hydrogen.

There’s another huge part of HYCO1’s breakthrough catalyst and process technology. When a small amount of water (H2O) is introduced into a HYCO1 CUBETM reactor along with CO2 and CH4 it breaks the H2O into H2 and O. The oxygen combines with free carbon and forms carbon monoxide and the hydrogen stays as chemical grade (high purity) hydrogen ready for any industrial use or for transportation.

CO2 is a Super Stable Molecule and a Low-Cost Feedstock

To understand and appreciate decarbonizing the world perhaps we should start by focusing on CO2, the primary waste gas causing climate change. Carbon dioxide is a super stable molecule. Once a carbon atom finds two oxygen atoms and forms CO2, it wants to stay as CO2. This is why over the past nearly 100 years, CO2 has been the tail end of industrial waste gases that is simply emitted to atmosphere and ignored instead of utilized. That is until 2020 when the world decided to start doing something about CO2 in the atmosphere and when industry started looking at CO2 through a different lens.

It takes a lot of energy to break the bond between a carbon atom and the two oxygen atoms that form CO2. HYCO1’s CUBETM Technology lowers the energy required to break or “crack” these bonds (called the energy of activation in physical chemistry terms) to a level that is cost effective. The remarkable thing is that the same CUBETM Process Technology that cracks CO2 also cracks CH4 in the same reaction at the same time. The base reaction can be expressed as:

1 CO2 + 1 CH4 → 2 H2 + 2 CO

The reaction takes place in seconds, is super-efficient (95+% conversion per pass), results in pure H2 and CO ready for downstream use, and importantly, does not coke up. The fact that there is no coking on the catalyst surface or in the reactor tube is why HYCO1 CUBETM Technology doesn’t need to be “power washed” with heavy steam flooding like traditional steam methane reformers. All of the CO2 and all of the CH4 is converted into H2 and CO and it’s done simultaneously and at the lowest cost of any existing technology.

So, for the first time in the history of planet Earth, one hundred percent (100%) of the CO2 fed into a CUBETM Reactor can be utilized instead of being vented as a waste gas to atmosphere. The same is true of methane. One hundred percent (100%) of the methane (whether from a pipeline or from RNG) can be utilized. This is carbon utilization at its best. This is why CO2 and CH4 can and should be viewed as low-cost feedstocks for making high value molecules.

Even more impressive is that HYCO1’s CUBETM Technology simultaneously cracks H2O alongside CO2 and CH4. When a small amount of water is added to the reaction (only the amount needed to produce the exact amount of additional hydrogen that is needed) the H2) almost instantly turns into additional hydrogen and carbon monoxide when reacted over HYCO1’s catalyst. The reaction can be expressed as:

1 CO2 + 1 CH4 + “X” H2O → “Y” H2 + 1 CO

HYCO1 process technology can produce 2 parts H2 to 1 part CO, no problem. By changing a few of the inputs, HYCO1 CUBETM Technology can produce 3 parts H2 to 1 part CO and even 4:1 H2 to CO. The same process technology can also be used to produce 100% CO if needed. Abundant, low-cost feedstocks that can be co-fed into a HYCO1 CUBETM reactor in differing amounts on the fly to produce virtually any ratio of hydrogen to carbon monoxide syngas – now that is a game changer in the world of decarbonization. It is a better way of utilizing carbon.

CO is a High Value Molecule Used to Make Many Downstream Products

Carbon monoxide is a very misunderstood but very high value molecule when it can be produced at scale alongside hydrogen. CO is often viewed as a harmful substance and it certainly is when it gets into the human body by mistake. But the truth is that CO is typically worth twice to three times more than hydrogen when producing downstream fuels, chemicals, and other materials. Because it is so reactive, carbon monoxide is used to make many carbon based downstream products which according to the Boston Consulting Group represents some $3.5 trillion in total global market potential1.

Virtually all fuels, chemicals, plastics, and other carbon-based materials start with carbon monoxide as a building block gas. Carbon monoxide and hydrogen reacted together utilizing various downstream process technologies are used to make products like:

Methanol

Diesel Fuel

Jet Fuel

Lubricants

Oxo-alcohols

Acetic Acid

Vinyl Acetate Monomer (VAM)

Amines and amides

At least for the next few decades, it’s hard to imagine a world without any plastics, paints, coatings, adhesives, cosmetics, and lubricants. All of these are produced from building block gases: hydrogen and carbon monoxide.

Hydrogen By Itself Isn’t the Answer

Hydrogen as a clean transportation fuel would be the perfect solution for the future of transportation and energy if it were super abundant, cheap to produce, and easy to store and transport long distances. But it is none of these.

Although hydrogen is the most abundant element in the universe, it only makes up a small fraction of Earth’s atmosphere. Therefore, unlike oxygen, which comprises about 21% of the air we breathe, hydrogen only comprises about 0.005% of air. If hydrogen doesn’t come from the air, then it must be produced from other substances. Currently there are two pathways for industrial scale H2 production: (1) methane reforming, and (2) electrolyzing water (H2O). Methane reforming accounts for the vast majority of hydrogen production today.

Industrial scale H2 production from CH4 is commonly referred to as steam methane reforming (SMR). It’s efficient but even using today’s best practices, steam methane reforming ultimately results in the production of CO2 – on average, about 9 kgs of CO2 for every kg of H2 produced.

Hydrogen production from electrolysis requires a lot of electricity. Current best processes for water electrolysis have an effective electrical efficiency of 70-80%, which means that to produce 1 kg of hydrogen (with a specific energy of 143 MJ/kg) requires 50–55 kWh of electricity. That same hydrogen can be converted back into electricity but only nets about 40 kwh.

Two additional hurdles for using hydrogen as a clean transportation fuel are storage and transportation. Both are complicated and expensive when it comes to hydrogen. Storage of hydrogen requires enormous amounts of energy to pressurize or liquify it which translates into huge capital expenditures and high operating costs (a great deal of which is energy costs). So, it takes a lot of energy to produce hydrogen and even more energy to store and transport it. Transportation of hydrogen is accomplished by high pressure tanks or vessels carried by trucks or rail because pipelines leak out the hydrogen too quickly. Hydrogen molecules are so small that they find their way out of virtually every type of container or pipe they are put in. Hydrogen also makes pipes and containers more brittle over time which creates long-term leakage and explosion hazards. For all of its pros, hydrogen has many cons.

Better Utilizing Carbon Is the Answer

There is no “silver bullet” to solve the decarbonization problem of the 21st Century. But when a carbon utilization technology comes along that allows 100% of the carbon from both CO2 and CH4 to be utilized into other products, it should be deployed wherever there is CO2 being emitted to atmosphere.

The answer to decarbonization is not to simply make more hydrogen nor is it to abandoning all fossil fuels entirely. Rather, it is better utilizing the carbon we have access to. Better and smarter utilization of carbon starts with using CO2 that is currently being emitted to atmosphere and using it as a feedstock that displaces and lowers the amount of fossil carbon introduced into the economy. Better utilizing the CO2 that the world is currently producing represents a huge step toward a circular carbon economy.

HYCO1’s perspective is that it will take many new technologies each working in complementary ways and each solving unique parts of the carbon utilization puzzle to create a fully circular carbon economy. HYCO1’s CUBETM Technology offers a new, extremely cost-effective way to begin utilizing CO2 and turning it from a waste gas into a productive low-cost feedstock.

- See the Boston Consulting Group: Can Carbon Help Decarbonize Chemicals; https://www.bcg.com/publications/2023/can-carbon-help-decarbonize-chemicals ↩︎

About the author: Jeff Brimhall - CFO & Co-Founder, HYCO1 Inc.

Jeff is a 5-Star deal guy with 35 years of funding experience and hands-on company building. His passion is funding sustainable technology companies, projects, and assets that make the world a better place to live and work. Over many years, Jeff has developed relationships with hundreds of funding sources, manufacturers, technology companies, and project developers. Through these relationships, he and his colleagues at Supraxis have developed practical expertise in providing strategic, programmatic funding solutions to help businesses scale up.

Jeff has a strategy and management consulting background from working at Bain & Co in Boston. He also has decades of energy project development and finance experience from his work at Energy Strategies and Sentry Financial. Just prior to founding Supraxis, where Jeff serves as a Managing Partner, he served as the President of the Sustainable Investments Division at Sentry Financial. Jeff earned a Bachelor’s Degree in Business Management and a Masters of Business Administration Degree both from Brigham Young University.

Recent articles

KTLA – HYCO1 Announces CUBE™ 2500 Small-Scale CO2 Reformer for Entry-Level, Low-Cost CO2 Utilization Applications

Ethanol Producer Magazine – How CCU Platforms Stack Up

Transforming Waste into Value