CUBETM 2500 CO2 Reformers

HYCO1's patent-pending CUBETM Technology now available for all. The only affordable, scalable CO2 utilization platform on earth.

From thousands to millions

of tons per year we can

convert CO2 at any scale

HYCO1's CUBETM CO2 Reformers are built with scale in mind. Whatever your CO2 utilization needs are, we can help. We are the only CO2 utilization technology that converts CO2 emmissions efficiently, profitably, and at scale.

HYCO1 CUBETM Technology cost effectively converts millions of tons per year of CO2 into millions of SCFD of H2 and CO!

HYCO1 CUBETM Technology cost effectively converts millions of tons per year of CO2 into millions of SCFD of H2 and CO!

Learn more about HYCO1's scalable syngas technology.

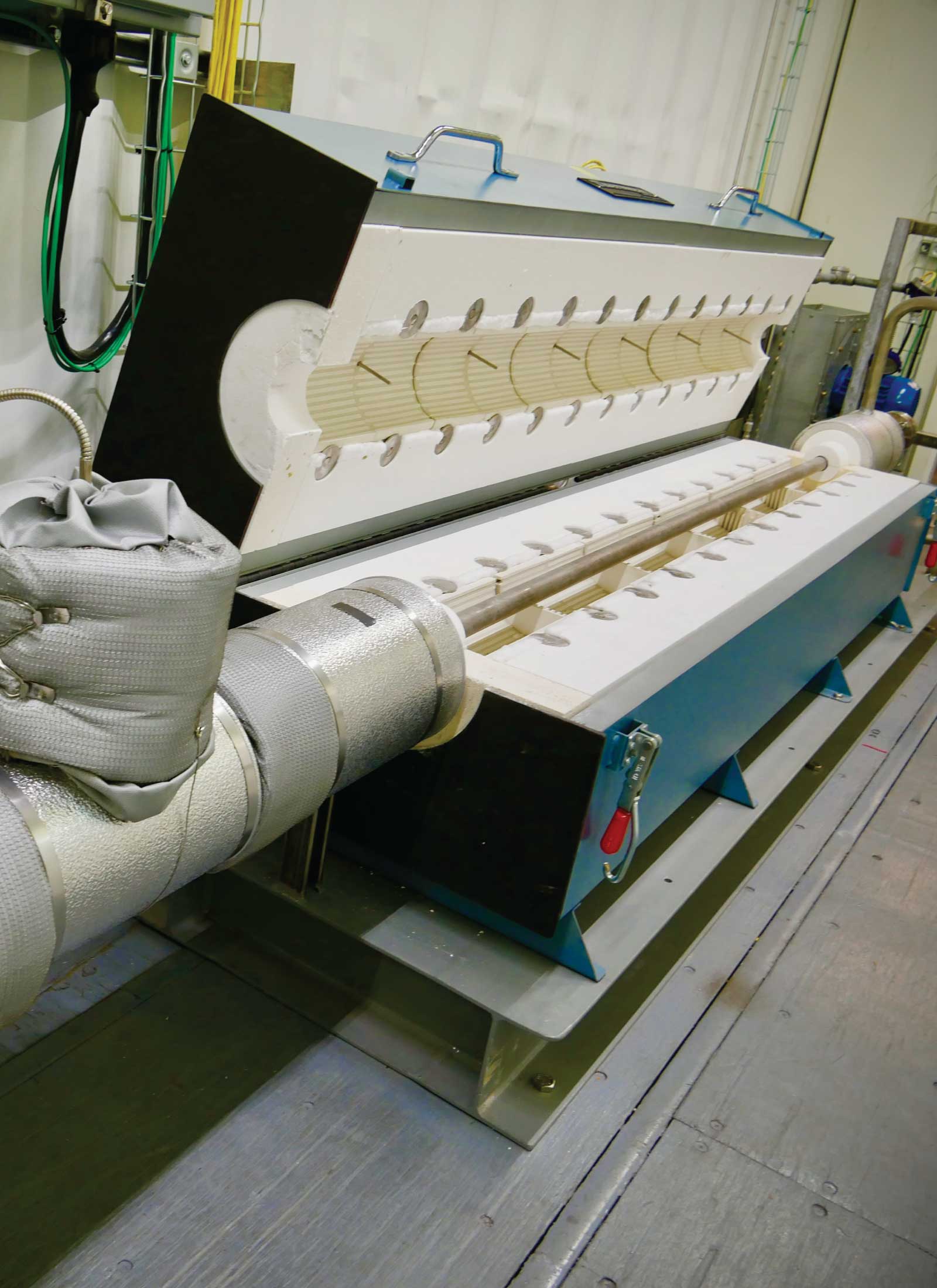

The CUBETM 2500 CO2 Reactor

• Turn-key small scale syngas production in flexible H2 : CO ratios

• Strategic Expansion of current syngas production

• CO production for specific products

• Decarbonization Strategies meeting corporate initiatives

• Strategic Expansion of current syngas production

• CO production for specific products

• Decarbonization Strategies meeting corporate initiatives

The first of its kind

The CUBETM 2500 CO2 Reformer converts CO2 at >95% in a single pass through the reformer. Powered by HYCO1’s CUBETM Technology (Carbon Utilization. Best Efficiency.), when CO2 is combined with various methane-rich feed sources, it produces the lowest-cost, lowest-CI, highest grade syngas (H2 and CO) that is available at scale in the market.

This has never been done before now.

Where are HYCO1 customers installing CUBE™ 2500 CO2 Reactors?

· Corporate Research and Development Centers

· Government Research Centers

· Chemical Parks

· Hydrogen Hubs

· Natural Gas Processing Plants

· Landfills

· Dairy Farms

· Wastewater Treatment Plants

· Other CO2 Emitting Facilities

· Corporate Research and Development Centers

· Government Research Centers

· Chemical Parks

· Hydrogen Hubs

· Natural Gas Processing Plants

· Landfills

· Dairy Farms

· Wastewater Treatment Plants

· Other CO2 Emitting Facilities

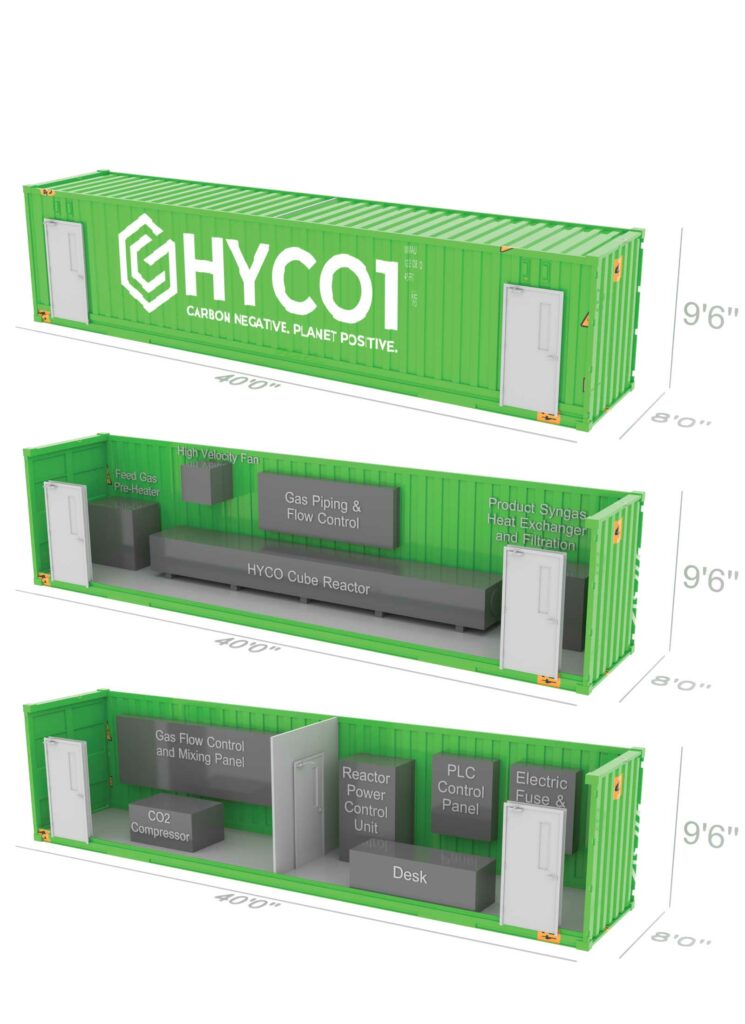

The CUBETM 2500 is a new entry-level, modularized, CO2 utilization syngas production unit for small scale commercial H2, CO, syngas, R&D, or proof of concept operations.

HYCO1 CUBETM Technology is available at customized sizes and with flexible hydrogen to carbon monoxide ratios.

HYCO1 CUBETM Technology is available at customized sizes and with flexible hydrogen to carbon monoxide ratios.

Learn more about HYCO1's scalable syngas technology.

The details

The CUBETM 2500 CO2 Reactor is a turn-key solution to CO2 emissions. Here's the details for engineering, installation, and operation.

• CUBETM Reformer 2500 built to process 2,500 TPA CO2 and 840 TPA Natural Gas in DMR / Dry Reforming Mode

• Built as two (2) 40-foot ISO Container modules, including a CUBETM Reformer Module and an Operations Module

• Four (4) standard high-alloy reformer reactor tubes with initial fill of HYCO1 catalyst

• Built as two (2) 40-foot ISO Container modules, including a CUBETM Reformer Module and an Operations Module

• Four (4) standard high-alloy reformer reactor tubes with initial fill of HYCO1 catalyst

• Electric heating, emissions free design

• Feed gas rates of 75 to 300 Nm3h

• CUBETM Reformer Module capable of ~500,000 SCFD Syngas Production, four (4) 30 ft length tubes @ 125,000 SCFD/tube

• Operating Pressure range of 2 bar-g to 20 bar-g

• Operating Temperature range of 750 to 1,000C

• Feed gas rates of 75 to 300 Nm3h

• CUBETM Reformer Module capable of ~500,000 SCFD Syngas Production, four (4) 30 ft length tubes @ 125,000 SCFD/tube

• Operating Pressure range of 2 bar-g to 20 bar-g

• Operating Temperature range of 750 to 1,000C

• Feed flexible for CO2, natural gas, boiler feed water, other approved hydrocarbons

• Complete gas flow control, measurement, and analytical systems

• Maximum Electric Power Requirement with Compressor is 650 kW

• PLC Control System

• Safety Systems and Interlocks.

• Complete gas flow control, measurement, and analytical systems

• Maximum Electric Power Requirement with Compressor is 650 kW

• PLC Control System

• Safety Systems and Interlocks.